AF14 SCM AFMI Stock Taking Warehouse Management

- Lakshminarasimman V Rao

- Nov 27, 2020

- 5 min read

AFMI -SCM -BL01M03-Day08-27Nov20 SC08-BL01M03

Agenda

systems analysis – techniques of logistics system analysis – factors affecting the cost and importance of logistics.

Stock Taking

What is the process of stock taking?

Stock taking or inventory checking is the process of counting, weighing or otherwise calculating all items in stock and recording the results. ... To verify the value of stock shown in the balance sheet by physical confirmation and value your stock in terms of cost and potential sales.

Purpose of Stocktaking

Stocktaking allows you to keep an accurate track of the physical stock you have, what's been sold, and what hasn't. It's all about comparing the physical stock to what the report says then finding any discrepancies

Efficient stock control allows you to have the right amount of stock in the right place at the right time. It ensures that capital is not tied up unnecessarily, and protects production if problems arise with the supply chain.

There are various techniques of stocktaking, defined below:

Periodic stock count.

Continuous or perpetual stock count.

Pick accuracy.

Stock-out validation.

Annual stock take.

Four main causes of inventory shrinkage:

Shoplifting,

Return fraud,

Employee theft, and.

Administrative error.

Benefits To Maintaining Good Stock Control

Increases productivity and efficiency. ...

Creates a more organised warehouse. ...

Helps save time and money. ...

Improves accuracy of inventory orders. ...

Keeps customers coming back for more.

best way

Use an EPOS system. ... An EPOS system, which stands for 'electronic point of sale system', can help small businesses like yours manage your business more effectively, and improve your customers' experience with you. They can speed up key business processes like accounting, stock management and sales performance

Figure out who is stealing. ...

Have security in place for both customers and employees. ...

Train employees. ...

Beware of scams. ...

Use RF/RFID tags. ...RFID a wireless technology that uses transmitted radio signals to tag an item in order to track and trace its movement without human intervention has superior capabilities over bar codes and promises many supply chain benefits, such as reductions in shrinkage, efficient handling of materials, increased product

Run a Live-stock system. ...

Use employee sign-ins.

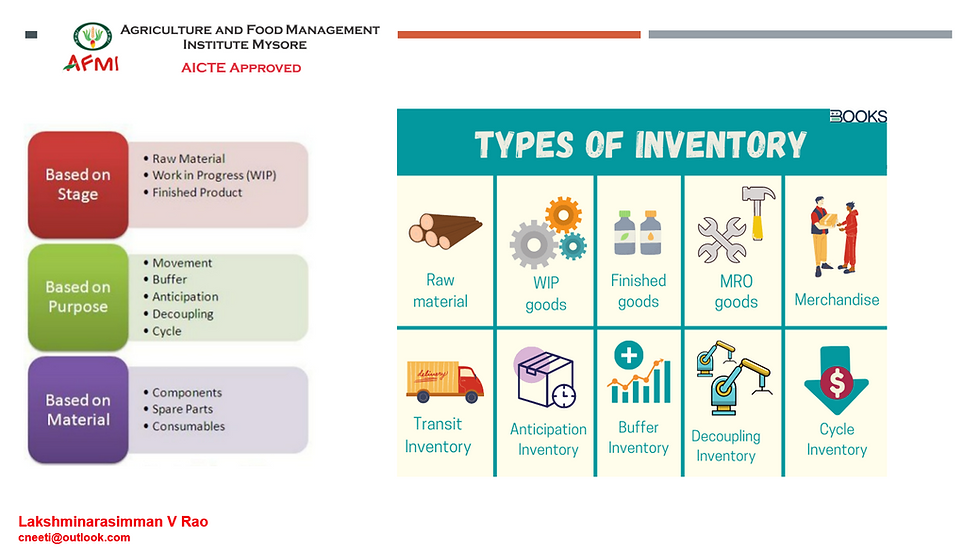

What are the 4 types of inventory?

The four types of inventory most commonly used are

Raw Materials,

Work-In-Progress (WIP),

Finished Goods, and

Maintenance, Repair, and Overhaul (MRO).

When you know the type of inventory you have, you can make better financial decisions for your supply chain

What is the main rule of stock rotation?

The golden rule in stock rotation is FIFO 'First In, First Out'. What is stock rotation? If food is taken out of storage or put on display, it should be used in rotation

What is continuous stock taking?

Continuous stock taking specifically means that stock-taking is conducted on a regular basis. ... Since entities can use this stock-taking method to ensure that they always maintain the right level of stocks to meet production requirements or customer demand, it also impacts the overall profitability of an entity

There are four accepted methods of inventory valuation.

Specific Identification.

First-In, First-Out (FIFO)

Last-In, First-Out (LIFO)

Weighted Average Cost.

Class Discussion

You are the purchase manager for Shridevi Paper Mills. You feel that wastage reported from the warehouse is more than the usual. How will you go about finding the cause and your suggestions to improve the better management.

Teacher' note: The students are encouraged to research on different reasons. there are various factors. No system is foolproof, however a good risk mitigation plan, coupled with latest technology and systems will help organisation in optimisation.

companies need to reduce the manual and labor-intensive warehousing process to more digitized and automatic

I will a take a look at the roof and floor of the warehouse and also keep the premises clean to eradicate the loss

Sorting of purchased goods based on quality

Set up a small team to check the wastage reports ,n make sure that next tym it doesnot happens

By reusing and recycling the waste

Investing in warehouse robotics technology will highly benefit

Reasons might be 1) poor layout of warehouse and 2 ) working efficiency of staff may vary..... suggestion is that proper planning of warehouse layout so that space for individual stuffs , machinery , working space should all be clean and well maintained to avoid waste.....staff should be properly trained so that each shift should work with same efficiency

First I enquiry about where the initial wastage occurring

Reasons might be less upgraded machines or double handling if materials or less skilled laborers and suggestions are to upgrade machines and to hire skilled laborers

To check the layer in paperboard. To ensure the stacking ability of paperboard.

Regular inspection about the wastage should be implemented

1st i will check where the wastage is more like due to transport, over production or waiting waste. Then to improve it i will sort them like warehouse layout avoiding multiple storage locations.

The first i checked the warehouse why the wastage is occur more than usual and given order to the warehouse workers that recycle the waste and use it again ..

Instead of manual work i prefer online mode of work which reduces wastage

Proper Inspection throughout the whole manufacturing process to check where they are using excess materials. My suggestion to reduce the wastage would be Chemical recovery and Recycling, Reducing costs and liabilities.

We can use the team in a better way and we can develop the quality according to customer

Recycling of wastes and making best use of

Regular inspection should be done (or) recycling of product

Labelling the product

Better machinery

using of right floor plan & enough space between products & fix

Class Discussion 2

If you have to catogorize the stock in your warehouse, what will be points you will consider before making the categorization?

Labelling, size, type

Based on the time , movement and also the value of the stock

Based on quality Grade

Quantity and quality.. size and shape of the product

Making a identification mark based on products category

Dividing stocks based on time period of their delivery, proper labeling..

Using right floor plan, having enough space between products and fixtures

Categorize the stock based on their delivery schedule like daily selling's weekly or monthly sellings

Palletization of stock. How to manage first in first out. Stacking ability of product

Categorizing the stock according to their movement like slow and fast moving goods

Transport waste, waiting waste, production waste

First label , boxes and containers in the warehouse e .place Place usefull thing in the front . make cleaining a first priority and place item according to uses and make a list of it.

I would like to categorize them based on quantity.

Based on the stages of manufacturing like raw materials and finished products and demand

Good infrastructure with all facilities

Keeping the same product in a stacking manner and marking it

Quality and size

Based on quality Grade

Based on material,

Palatization

Sufficient space maintenance for each group,

Lakshminarasimman V Rao | SCM| Class notes | Study Material | AFMI | Corporate Neeti Consulting | Mysuru

All data above is a combination of data from Internet, purpose of this doc is for research and education only and responses received from Class students and interaction.

https://g.page/corporateneeti?gm

https://fb.com/corporateneeti

Comments